The white shrimp, scientifically known as Litopenaeus vannamei, also referred to as Penaeus vannamei, Pacific white shrimp, or king shrimp, is a species commonly caught or farmed for food in the eastern Pacific region.

Throughout the 21st century, L.vannamei has become a valuable resource for fishermen and consumers alike. Shrimp is a popular seafood choice worldwide due to its abundance of omega-3 fatty acids, calcium, iodine, and good cholesterol. Moreover, it contains lower levels of mercury compared to other seafood options. Its versatility in various cuisines, especially in Asian dishes, has led to high demand and significant market growth.

The popularity of this product continues to surge globally. Advancements in shrimp farming techniques, including the availability of cultivable larvae, improved feed development, growth process technicalization, freezing facilities, and efficient market channels, have fostered the growth of the shrimp farming industry across different regions and in various dimensions and types. As a result, the industry remains on a path of continuous expansion.

The female shrimp mates with the male shrimp and lays up to a hundred thousand eggs in the water.

The fertilized eggs develop into Nauplius stage, which grows to a size of 0.32-0.58 millimeters. At this stage, the shrimp still lacks a complete digestive system and feeds on the yolk sac.

The Nauplius sheds its yolk sac and undergoes molting, transforming into a Protozoea. In this stage, the shrimp starts to feed on the surrounding environment, such as phytoplankton.

The shrimp undergoes three more molting stages to become a Mysis. The most notable developments at this stage are the appearance of swimming legs (pleopods) and the addition of body segments. The size of the Mysis shrimp reaches 3.50-4.80 millimeters.

When the Mysis shrimp reaches the post-larval stage, it looks similar to an adult shrimp. At this stage, the shrimp become actively mobile and move forward. Additionally, to inform farmers about the age of post-larvae, a number is added to them; for example, one-day post-larvae.

When the shrimp reaches PL 10 or ten days after hatching, it is considered a juvenile.

A shrimp that is 80 to 90 days old can be called a young shrimp or sub-adult. Typically, the weight of these young shrimp reaches 21 to 23 grams per head.

To reach harvest-ready adult shrimp, the juvenile shrimp requires around 25-30 days and reaches an average weight of 28-30 grams per head.

Advantages of cultivating Vannamei shrimp:

Since the discovery of this shrimp, Vannamei shrimp has immediately become one of the potential export commodities. This is because these shrimp, originally from semi-tropical regions, have excellent environmental resistance and can quickly adapt.

In addition to this, several other advantages, such as high economic value, faster growth, greater resistance to diseases and unstable environments, and high shelf life, make Vannamei shrimp the preferred choice for farmers.

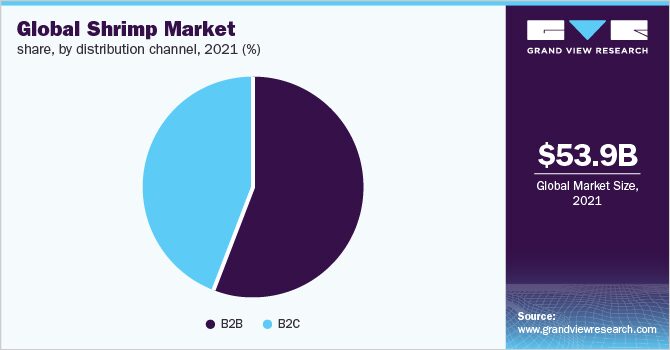

Distribution Channel Insight

The B2B sector had a large share of more than 55% in 2021. It is expected to grow by 5.0% during 2022 to 2024. The large contribution of this sector is attributed to the wide use of shrimp of different types. Industries including food, pharmaceutical, health, and cosmetic industries. Shrimp is widely used in various businesses, for example, in the hospitality industry, including restaurants, hotels, etc., all of which have led to the growth of this market in B2B business.

B2C sectors include hypermarkets and supermarkets, convenience stores, specialty stores, online stores, etc. The B2C segment is expected to grow faster than 5.7% during the forecast period from 2022 to 2030. Several business operations serving the B2C sector focus on direct wholesale purchases to minimize shrimp procurement costs. These products are offered directly to consumers and thus their acceptance increases. Moreover, the increase in the use of online channels due to its various benefits such as time-saving, discounts, and other offers in the B2C sector will further grow this sector.

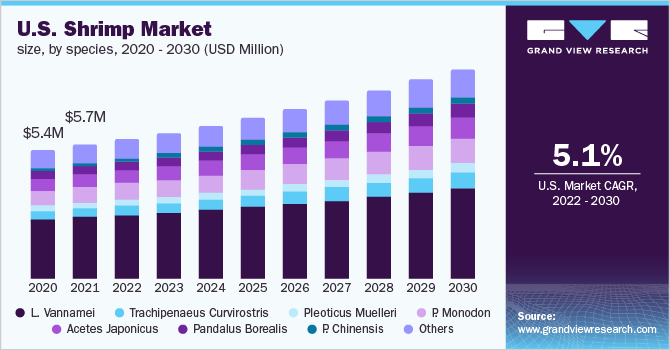

We now examine revenue growth at the global, regional, and country levels and provide an analysis of the latest industry trends in each sub-sector from 2017 to 2030. For this study, we have used Grand View Research, which has segmented the global shrimp market by species, source, form, distribution channel, and region:

Species (Revenue, USD Million, 2017 – 2030)

Source (Revenue, USD Million, 2017 – 2030)

Form (Revenue, USD Million, 2017 – 2030)

Distribution Channel (Revenue, USD Million, 2017 – 2030)

Regional (Revenue, USD Million, 2017 – 2030)

Biosecurity is often overlooked in vannamei shrimp farming because the financial advantages of incorporating it into infrastructures and specialized methods are uncertain. On the other hand, biosecurity cannot be underestimated as it is one of the most effective ways to prevent diseases on the farm and reduce their prevalence in the region. This benefits not only individual farmers but the entire aquaculture community. So, what is biosecurity?

In simple terms, it is the best method to prevent diseases. Biosecurity is a set of techniques that eliminate specific diseases from the aquaculture stocks in hatcheries, nurseries, farms, and even entire regions or countries. It protects the products by preventing the entry of pathogens and keeping disease-causing agents at bay.

This article outlines some of the fundamental biosecurity measures that you can implement on your farm currently.

Doing this is really simple, but it’s truly one of the fundamental keys to shrimp farming. Protect the farm with fences to keep wild creatures like crabs or birds, which could cause harmful infections to shrimp, away.

High-density polyethylene (HDPE) is the most common material used for pond liners. Using a pond liner makes water management easier because the water doesn’t come into direct contact with the soil, which can lead to a complex oxygen-depleting reaction that is highly toxic to shrimp. Liners successfully prevent water and soil interaction, prevent soil acidity, stop the adjacent areas from becoming saline, and control water leakage into the ponds in waterlogged areas.

Install a handwashing station, footbath, wheel wash station, or rubber bath. Install a warning sign to ensure that the workers’ shoes are disinfected before entering the facility. Worker attire is essential to ensure that all employees and visitors undergo disinfection and cleansing processes before entering and working. Before entry and exit, all vehicles must adhere to the same protocols.

To maintain cleanliness and prevent contact with external agents that can cause diseases, store feed and probiotics in a separate storage room and create a stable temperature for the well-being of the shrimp’s nutrition.

Laboratories are essential for two crucial purposes: water quality determination and disease investigation. Having a reliable laboratory in your area is highly beneficial because conducting these tests locally is much faster than sending water or shrimp samples to another city.

Sterilization is a vital step to ensure shrimp are kept in a disease-free environment. To eliminate pathogens and minimize the risk of disease, all components of the farm must be sterilized before starting storage. This includes the ponds themselves, equipment, and the water used for cultivation.

Where to Begin:

Start by cleaning the ponds and equipment with a high-pressure spray containing disinfectants. It is recommended to use chlorine, trichloroisocyanuric acid (TCCA), and 30 ppm sodium hypochlorite. After disinfection with chlorine, wash the pond’s lining to make sure the biofilm has been removed. Next, remove all remaining sludge from the previous cycle, as this area can be a source of disease-causing agents and harmful elements. If the farm has experienced disease outbreaks in the previous cycle, use lime with a pH of 11 to eradicate any pathogens and prevent further spread in the next cycle.

To monitor the presence of pollutants in the water of shrimp farms, toxicity tests should be conducted for both solid particles and gases. These tests examine how aquatic organisms react to the presence of harmful chemicals such as ammonia, nitrites, and nitrates. It’s essential to note that the dosage of these chemicals varies depending on the shrimp species being cultured. The toxicity test shows the threshold at which the above-mentioned compounds start affecting the shrimp.

Water sterilization requires two stages: pre-treatment and disinfection.

For pre-treatment, use filters with a mesh size of less than 200 to 300 microns at the water inlet to prevent the entry of disease-causing agents, predators, and undesirable settling solids. Filters should be regularly cleaned with clean water to eliminate any sediment.

When it comes to water disinfection, use chemical disinfectants to eradicate all microorganisms. Add 20 to 30 ppm of 60% sodium hypochlorite, 0.5-2.5 ppm of KMnO4, and 10 ppm of TCCA to the purified water for 24 hours. During chemical disinfection, maintain maximum aeration. To get rid of any remaining chlorine, triple the amount of residual chlorine and add the appropriate amount of sodium thiosulfate. Finally, repeat this process two to seven times within 24 hours.

By providing this information, we aimed to assist you in understanding and entering the field of shrimp farming. We hope that the above-mentioned information will provide you with a clearer insight and enhance your productivity in this industry.