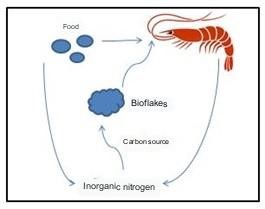

Biofloc systems have gained recognition as a valuable natural resource rich in protein and fat within aquaculture ponds (Avnimelech, 2007). These systems provide essential nutrients, including vitamins and minerals, derived from the biomass present in breeding ponds, making them a suitable supplemental food source for aquatic animals (Xu and Pan, 2014).

Shrimp producers exploring biofloc technology may find an opportunity to reduce the protein content in shrimp diets while maintaining performance, as evidenced by recent research findings. However, the successful operation of biofloc systems hinges on the provision of exogenous carbon sources, maintaining an optimal carbon-to-nitrogen ratio to foster the growth of microbial colonies.

Numerous studies have evaluated the impact of various carbon sources and concentrations on water quality, growth performance, and feed utilization in shrimp rearing within this systems. These studies have assessed a range of carbon sources, including starch, glucose, sugarcane bagasse, sugarcane molasses, rice bran, rice flour, wheat bran, wheat flour, cassava flour, gram flour, cornflower, and crop residues.

Although not all carbon sources exhibit equal efficiency in supporting this production, certain substrates have shown promise due to their ability to facilitate rapid ammonia removal and higher volume production.

One particularly promising study investigated the effect of dietary protein levels (250, 300, and 350 g protein/kg) in conjunction with two distinct carbon sources, sugarcane bagasse (SB) and wheat flour (WF), on enhancing Vannamei shrimp production, feed utilization, and water quality in this system. The results yielded noteworthy findings:

The crude protein content in this system, found in SB300, WF300, SB350, and WF350 treatments, significantly increased with higher dietary protein levels.

Wheat flour as a carbon source notably increased lipids and nitrogen-free extracts in biofloc.

Shrimp raised in biofloc treatments with diets containing 250, 300, and 400 grams of protein per kg outperformed the control groups with diets containing 450 grams of protein, indicating the compensatory ability of shrimp in this systems for reduced dietary protein levels.

SB350 and WF350 treatments demonstrated the best growth performance compared to the control group, further supporting the idea that lower protein diets can be compensated for in biofloc-fed shrimp.

Vannamei shrimp’s growth performance remained unaffected by varying protein levels, suggesting that in this technology systems, dietary protein levels can be safely reduced from 450 g to 350 g protein/kg, leading to improved growth and feed utilization.

Given the significance of the shrimp farming industry, the adoption of biofloc technology can play a pivotal role in enhancing breeding practices. Biofloc systems, driven by active heterotrophic bacteria, effectively absorb excess nitrogen, producing biomass that can be consumed by shrimp. This approach not only strengthens shrimp safety and the potential for biological safety on farms but also boosts shrimp performance, growth, food conversion ratio, and water quality.

Effective control of total ammonia nitrogen and nitrite levels is achieved through heterotrophic uptake and autotrophic nitrification, maintaining these parameters within acceptable ranges for shrimp farming even at high stocking densities.

By implementing biofloc systems, producers not only reduce their reliance on fish meal, lower dietary protein percentages, and reduce production costs but also have the potential to produce high-quality organic shrimp for export markets while benefiting from the environmental advantages of this modern breeding technology.

In regions where white spot disease is endemic and the disease agent is consistently present in seawater, adopting biofloc systems without water exchange becomes a valuable strategy for shrimp farming. However, implementing this system in brackish water areas necessitates pilot studies due to high salinity and evaporation rates. Collaboration among fisheries organizations, aquaculture researchers, and shrimp farmers is vital to establishing biofloc systems as the foundation of sustainable Vannamei shrimp aquaculture.

We hope this article has provided you with a clearer grasp of this topic.

To read more articles, click here.

“Maturation and Spawning in Captivity of Penaeid Shrimp: Penaeus merguiensis de Man Penaeus japonicus Bate Penaeus aztecus Ives Metapenaeus ensis de Hann Penaeus semisulcatus de Haan”. Proceedings of the Annual Meeting – World Mariculture Society.